Shoreditch Village Phase II, London

Main Façades for an Office Building near Shoreditch High Street Underground Station

Located in the northeastern city center, the London Borough of Hackney is home to the district of Shoreditch, a renowned fashion hub of the city. Currently young, and established designers alike are developing exclusive fashion trends and future labels there.

Following the construction of a hotel, residential, and commercial building in Phase I, Phase II saw the development of a complex comprising nearly 7,500 m² of office space and 2,500 m² of retail space by investment fund Brockton Capital. GIG successfully secured the façade contract for this project.

In addition to approximately 2,700 m² of unitized façades, nearly 2,300 m² of curtain wall façades, rainscreen façades, balustrades, and ceiling soffit claddings were manufactured.

A particular challenge in this project was the partially exposed external structure in the form of a fire-rated steel construction. Both in the planning phase and especially during installation, overcoming the challenges posed by these structural penetrations required careful consideration.

2.670 m²

Unitized façades

2.270 m²

Mullion-transom façades

670 m²

Sandwich panel constructions

580 m²

Aluminium cladding

130 rm

Balustrades

Requirements

Meeting special acoustic requirements

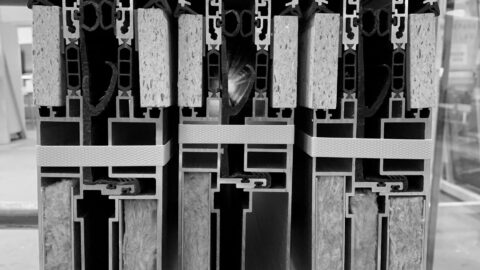

Unitized façades can be optimized for high acoustic requirements by integrating special multi-layer constructions with soundproofing materials. The use of heavy laminated glass and sound-absorbing insulation minimizes sound transmission. Additionally, decoupled façade constructions or strategically placed cavities with absorbers can be used to reduce disruptive frequencies. This results in a high-performance building envelope that combines excellent sound insulation with architectural aesthetics.

Fluted ceiling panels – Design, manufacturing, and innovative fastening

For the ceiling fascia area, fluted sheets made of blackened stainless steel were chosen as a design element. The architect placed particular emphasis on the aesthetic effect and color of the sheets, which is why the selection process involved a comprehensive sampling procedure with various patterns.

The sheets were manufactured using hydro-mechanical deep drawing (Hydroforming) to precisely create the desired structure. A key detail was the invisible fastening, which enhances the elegant appearance. To achieve this, a specially adapted fastening system had to be developed. The final solution – an adhesive technique – was thoroughly tested in the in-house testing department and successfully validated for its suitability.

Assembly of Elements on an Exoskeleton Steel Load-Bearing Structure

In the exoskeleton structure, the load-bearing elements are arranged on the outside. This allows for more flexible interior design, as fewer supports or load-bearing walls are needed. The challenge for the façade construction lies in the penetrations of the façade, which must accommodate movements due to temperature fluctuations and load deformations. At the same time, it is essential to avoid thermal bridges and energy losses.

The façade was implemented as an unitized façade, which can typically be assembled without scaffolding. However, for the assembly, a rolling scaffold was developed, standing on the concrete floor, with an outward-swinging working basket. This allowed the installers to precisely finish the penetrations from the outside after the element assembly. Additionally, this scaffold was used for the final quality control of the façade penetrations to ensure perfect execution.