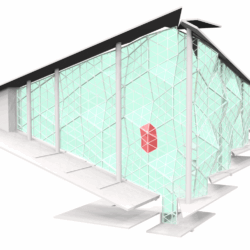

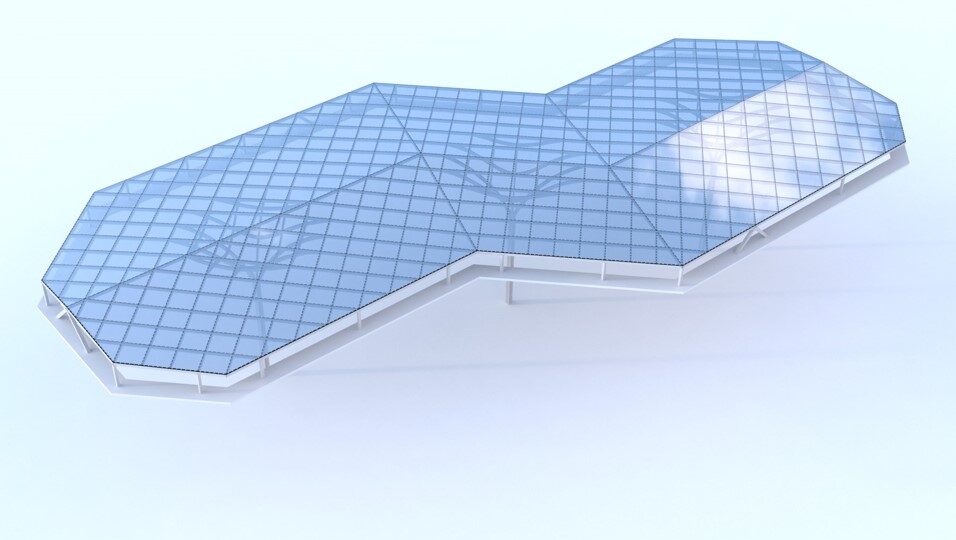

Maximum freedom in form and space

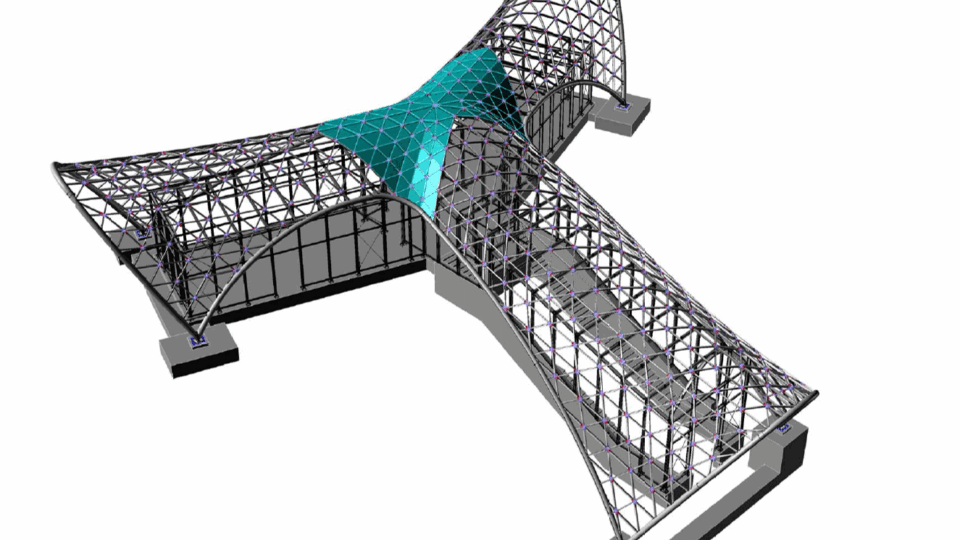

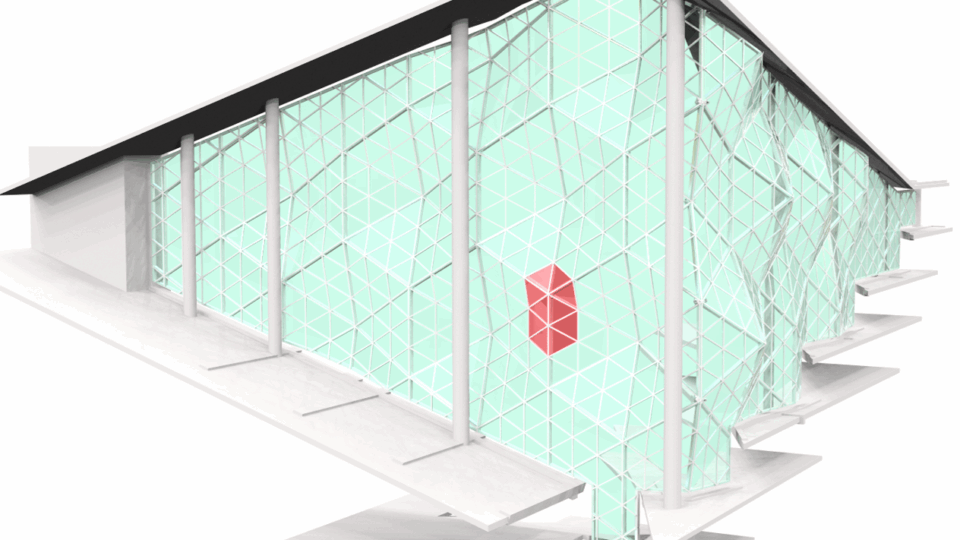

With its airy and seemingly floating appearance, it is one of the supreme disciplines of architecture: the freeform steel and glass supporting structure is unmatched in its ability to envelop large areas in a unique way.

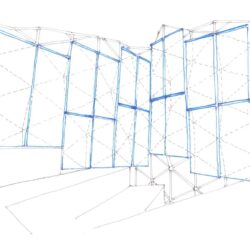

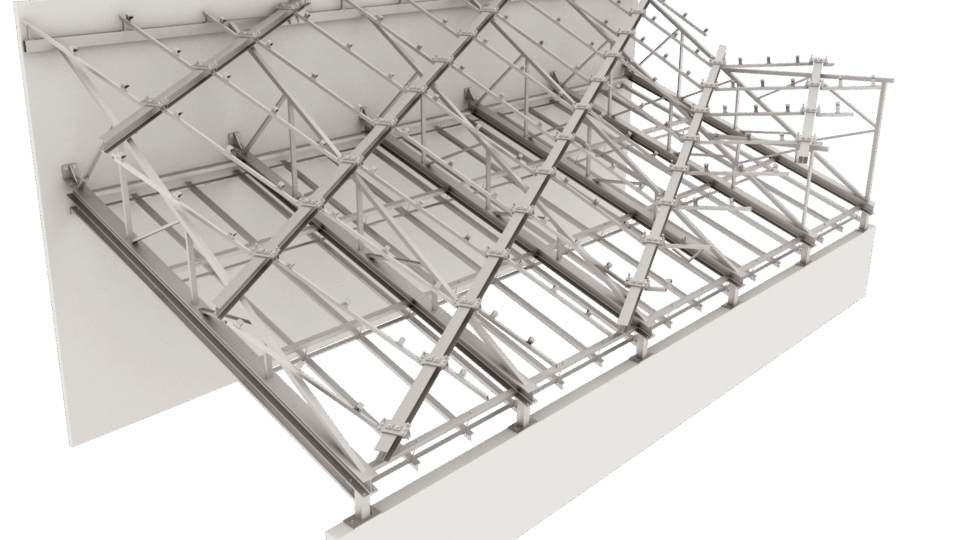

However, the more demanding the structure, the more important meticulous planning in advance becomes. The development and implementation of our fascinating unique pieces is a multi-stage and highly complex process: Through very close cooperation between the architect, specialist planners, and GIG, freeform surfaces with character emerge.

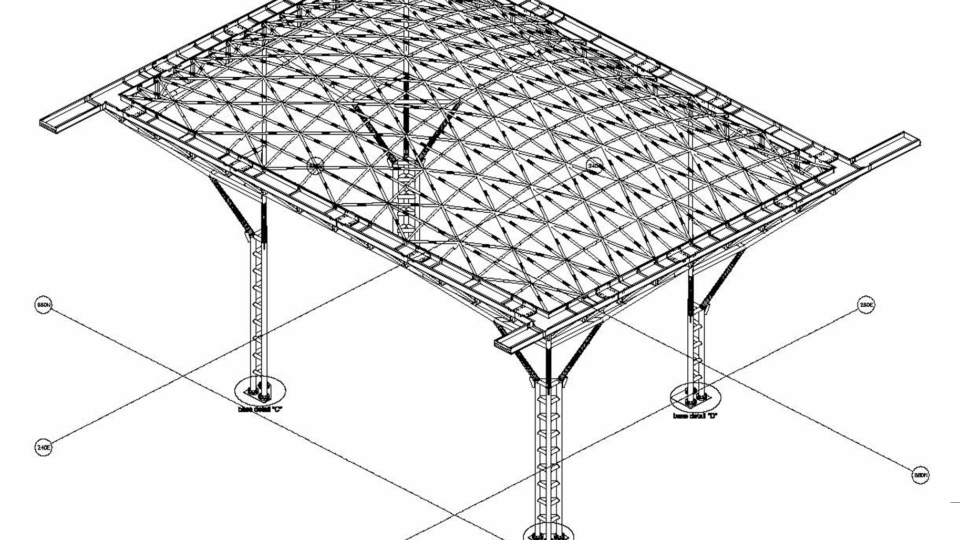

Making the concept feasible

The process begins with the architect’s design, where the vision and basic concept for the freeform structure (e.g., for a roof construction) are developed. At the same time, an initial static calculation is prepared. After initial calculations regarding the load-bearing capacity and stability of the structure, the predefinition of spans, glass sizes, and divisions begins.