Cube, Berlin

Modern Glass Sculpture

The Cube project is prominently located near the central railway station in Berlin at Washington Place. The Cube shape is characteristic for this project, whereas the façade is executed as a double-skin façade.

The inner layer features a unitized window façade with interior pilasters and external sun shading. Steel structures support the outer shell, which consists of glass panels fixed in the glass joints.

An eye-catcher on the glass façade are the balconies, which cut into the building envelope from all views on different floors.

7.200 m²

Exterior envelope corresponds to:

1.816 Stk.

Glass panes

1.247 Stk.

Storey-high windows as part of the internal façade

6.300 m²

Internal façade

210 tons

Steel

Requirements

Process for reducing Anisotropy in Glass

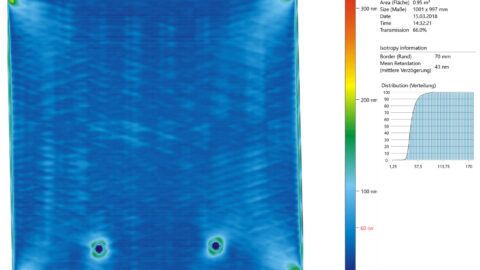

Heat-treated glass is an anisotropic material. In large glass surfaces, this anisotropy can manifest as a kind of cloud formation on the glass under certain lighting conditions. Measurement methods and test values in the area of anisotropy are not yet standardized. To optimize the appearance of the glass surfaces, the customer requested a reduction in the anisotropy of the external glass panes. Therefore, a method was developed in collaboration with the glass manufacturer and the facade planner to directly test the glasses after production according to agreed-upon quality criteria. The following parameters were considered:

- Approved glass panes as reference objects,

- Regulation of the cooling rate in the annealing furnace,

- Scanning of each individual glass pane = visualization of the distribution of anisotropy in the glass.

Using this method, the glasses were able to be tested against all criteria, and all required values were met.

Duplex coating on laser-welded profile tubes

Duplex systems are a form of corrosion protection for laser-welded or rolled steel profiles consisting of hot-dip galvanizing and wet paint coating. Instead of wet painting, powder coating could also be used.

Hot-dip galvanizing is achieved by immersing the steel profiles in the zinc bath. This protects the entire surface of the profile (including hollow profiles); the thickness of the hot-dip galvanizing layer is defined by DIN EN ISO 1461.

Coloring is done using a wet paint coating consisting of primer and topcoat, also with defined layer thicknesses. To prepare the galvanized profiles for wet painting, they are swept. Sweeping is a gentle form of sandblasting to achieve optimal adhesion for the subsequent coating. Further irregularities on the steel surface can be smoothed out through fillers and grinding. Sampling and execution quality were defined in close cooperation with the customer.

Glass clamping holder for glasses in various clamping angles

In the construction project for the office building Cube in Berlin, a glass clamping holder was needed to secure the impact discs (exterior glasses), capable of covering various clamping angles to describe the complex geometry of the facade. Therefore, in close collaboration with a structural engineer, GIG developed an articulated glass clamping holder.

To assess and demonstrate the suitability of the holder for this purpose, successful pendulum impact tests were conducted in the in-house testing department.

Approval of impact-resistant glass panels with special characteristics

During the construction of the office building Cube in Berlin, the exterior facade was intended to be executed with clamp holders. High demands were placed on fall protection glazing as well as the installation situation of overhead glazing. For architectural reasons, the impact-resistant panels were to be made of two-layer laminated safety glass (LSG) with two different PVB films and a coating towards the PVB film.

In combination with the installation situations, there is no building product regulated for the German market, nor is the proof of residual load-bearing capacity of clamped overhead glazing regulated in DIN 18008-3.

For these reasons, a project-related construction approval (formerly approval in individual cases, ZiE) was required for the building product “LSG with coating towards the film” in combination with a project-related usability proof for the clamped horizontal glazing or for the clamped glazing with fall protection function.

For this purpose, pendulum impact and residual load-bearing capacity tests were required, which were successfully conducted in our own testing facility with an external testing institute and approved by the authorities.

.