Manufacturing - Perfect shaping for your vision

We bring ideas into perfect form

What is the foundation of our international reputation as manufacturers of exceptional façades? It lies in years of experience, maximum expertise and, not least, our highly specialized machinery, which enables us to develop precise and efficient solutions for your individual requirements. Our expertise particularly lies in sheet metal processing, mechanical machining of metals, and the completion of façade elements with glass, ceramic, terracotta, natural stone, and enamel sheets.

Another focus of our activity is the completion of façade components. Our unitized curtain walls, stick systems, windows, and doors meet the highest aesthetic and functional requirements.

We are your reliable partner when it comes to cutting, shaping, and joining aluminum profiles and sheets. Our professionals in various welding technologies and state-of-the-art equipment enable the precise and efficient processing of a variety of materials to deliver high-quality products to you. Speaking of delivery: we package your parts according to international shipping requirements, including all necessary export documents!

Completion

Thanks to our state-of-the-art technologies and experience in pre-assembly, we manufacture customized façade elements that meet the highest aesthetic and functional demands. From the installation of unitized curtain walls to stick systems, windows, and doors, we offer a wide range of options to meet your individual requirements.

GIG employees assembling the element frame, © GIG

Element façade manufacturing with a focus on precision and custom materials

Our core competence lies in the production of unitized curtain walls in small and medium series. In our testing department, pilot series are built and processes for serial production are optimized. Here, we can also utilize our extensive experience in processing special materials: whether it’s precast concrete elements, terracotta, ceramic, glass fiber reinforced concrete (GRC), glass fiber reinforced concrete (GFRC), wood, stone, natural stone, enamel sheets, glass, aluminum, steel, or stainless steel – we master the processing of these materials with the highest precision and quality.

Cutting

Our CNC bar machining centers enable precise machining of aluminum profiles up to 7 meters in length. With an optimized CAM interface for job preparation, profiles can be completely and efficiently processed. The result is high-quality components that meet the highest quality standards.

Our punching-nibbling machine is ideal for sheet metal processing. With a capacity of 2×6 meters, it allows for precise manufacturing of holes, slots, countersinks, threads, and other shapes in 1mm, 2mm, 3mm, 4mm, and 5mm aluminum sheets for various applications.

Employee loading work orders, © GIG

Precise cuts and efficient metal processing for your requirements

We also have powerful double miter saws for precise cutting of aluminum profiles and other metals. These machines ensure exact cuts and high efficiency in material processing. Notching saws and punches complete our equipment to meet your specific requirements for metalworking.

Shaping

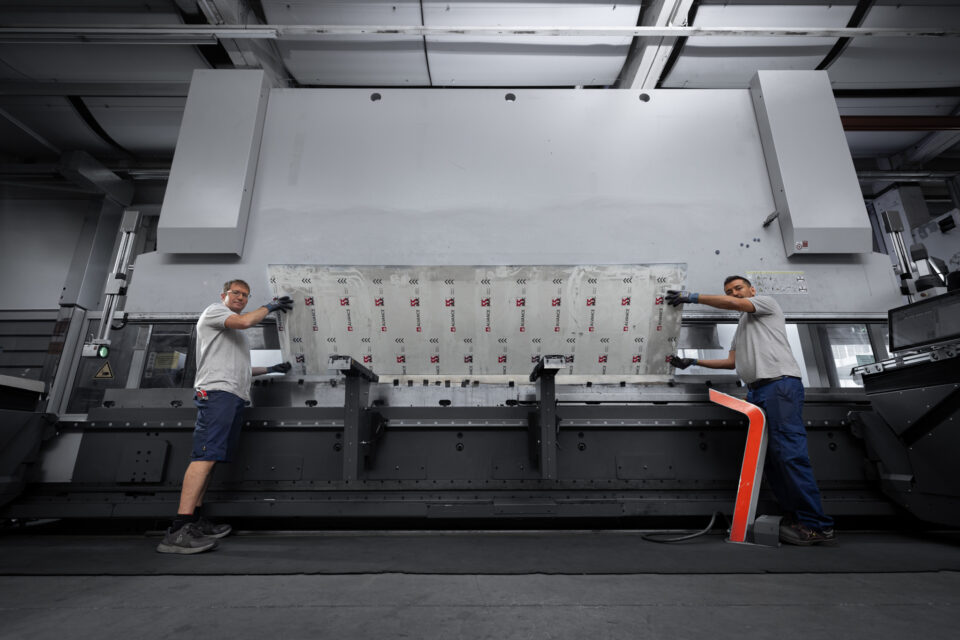

We have extensive expertise and the necessary technologies for high-quality forming operations in different sizes and materials.

Our press brakes with a length of up to 6 meters enable us to bend and shape complex sheet metal parts to the required size with high precision and accuracy. We ensure that your sheet metal parts achieve precisely the desired shapes and angles. Special sheet metal boxes, pilasters, and features can thus be produced.

Working at the bending press, © GIG

High-quality sheets and surface finishing – customized for your project

Our comprehensive sheet metal warehouse includes small, medium, and large format sheets in aluminum, steel, and stainless steel. For aluminum sheets, we distinguish between anodized quality (Almg1, J57sUP, EN AW-5005) and standard quality (Al99.5, EN AW-1050). Surface protection in the form of powder coating and anodizing is carried out by our partner companies.

Joining

Our team of qualified welders masters a variety of welding processes, including MIG welding (Metal Inert Gas Welding) such as MIG 136, MAG welding (Metal Active Gas Welding) such as MAG 135, as well as oxyacetylene welding for specific requirements. Furthermore, we are trained in TIG welding (Tungsten Inert Gas Welding) according to the WIG 141 procedure, which is particularly suitable for stainless steel and aluminum. These processes enable us to weld a wide range of metals precisely and efficiently. For concealed screw connections on sheets, we use welding studs.

As a certified company according to EN1090, you can trust that we adhere to the highest quality standards. Certified in classes EXC1, EXC2, and EXC3, we are capable of welding and testing metal structures with different requirements for strength and reliability.

©GIG/Felix Friedmann Photography

Adhesive connections also play an important role in metal construction

We have extensive experience in structural glazing and are approved for bonded glass constructions according to ETAG002. We are proud to be a DOWSIL-certified company, and our experts ensure a safe and durable connection between glass and metal. To ensure precise and reliable dosing of adhesives in serial production, we use state-of-the-art 2k mixing and dosing systems. With this technology, we can achieve the optimal mixture of adhesives and ensure uniform and efficient bonding of metal components.

Packaging & Transport

In addition to custom metal construction solutions, we also offer comprehensive solutions for the packaging and transportation of your façades and elements.

We understand the importance of ensuring that your metal components arrive safely and protected at their destination. Therefore, we place great emphasis on transport-appropriate packaging and a reliable transportation process. For the safe transport of your products, we rely on reusable racks. These specially designed and TÜV-tested racks provide a robust and stable packaging solution that is ideal for repeated use. Our reusable racks not only ensure the protection of your metal components but are also environmentally friendly and support sustainable logistics. For international shipping, we ensure that your products are packaged in transport-appropriate packaging.

The elements are prepared for shipment, © GIG

On-time Just-in-Time delivery with comprehensive customs and documentation handling

Our experienced team handles the necessary customs formalities and ensures that all required documents and permits are in order. This ensures that your products reach construction sites in destination countries smoothly and without delays.

We deliver just-in-time from Attnang-Puchheim to our international construction sites. With our efficient logistics management, we ensure that your products are delivered on time and in perfect condition

Contract manufacturing

We offer our expertise in sheet metal processing, bar processing, and assembly for contract manufacturing.

If you have any questions or need further information, we are always happy to assist you. Don’t hesitate to contact us – we are here for you!